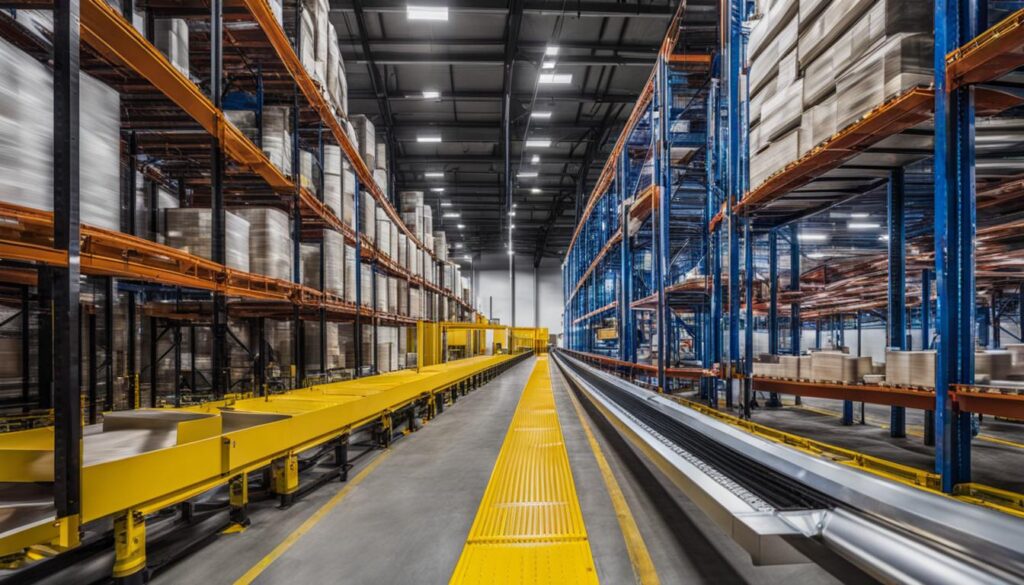

At our company, we understand the importance of optimizing material handling processes to achieve operational efficiency. One key solution that has proven to be highly effective is the implementation of conveyor systems. These systems play a critical role in streamlining operations, reducing labor costs, and improving overall productivity.

Conveyor systems offer a range of benefits when it comes to material handling. By efficiently moving materials from one location to another, they help to eliminate manual handling and reduce the risk of errors or damage during transportation. This leads to cost savings and improved product flow, ultimately enhancing the productivity of your operations.

Key Takeaways:

- Conveyor systems are essential for optimizing material handling processes.

- They reduce labor costs and improve productivity by efficiently moving materials.

- Implementing conveyor systems leads to reduced operational costs and enhanced product flow.

- Optimizing material handling with conveyors increases overall operational efficiency.

- Custom conveyor solutions tailored to specific needs offer scalability and long-term benefits.

Why You Should Prioritize Optimizing Your Material Handling Process with Conveyors

When it comes to optimizing your material handling process, incorporating conveyor systems should be at the top of your list. These systems offer a wide range of benefits that can have a significant impact on your overall operational efficiency. By prioritizing material handling optimization with conveyors, you can achieve cost reduction, improved productivity, and enhanced safety in your facility.

One of the key advantages of conveyor systems is the improved time and space management they provide. By automating the movement of materials, conveyors reduce downtime and allow your employees to focus on more mentally-demanding tasks. This not only increases overall productivity but also helps create a more efficient workflow. Additionally, by streamlining the material handling process, conveyors require fewer resources and can help reduce operational costs.

Furthermore, integrating conveyor systems into your material handling process can have a positive impact on product quality. By minimizing manual handling, conveyors help prevent product damages, ensuring that your goods arrive at their destination in optimal condition. This, in turn, improves customer satisfaction and reduces the need for costly returns or replacements.

Benefits of Optimizing Material Handling with Conveyors:

- Cost reduction through improved time and space management

- Increased productivity by streamlining material handling processes

- Enhanced product quality through reduced manual handling

- Improved safety by minimizing physical strain on employees

By prioritizing the optimization of your material handling process with conveyors, you can achieve a more efficient and effective operation. The benefits of cost reduction, improved productivity, and enhanced safety make conveyor systems a strategic investment for any business.

| Conveyor Systems Benefits | Cost Reduction | Productivity Improvement |

|---|---|---|

| Improved time and space management | Reduces labor costs | Streamlines material handling processes |

| Enhanced product quality | Minimizes handling costs | Requires fewer resources |

| Prevents product damages |

Key Elements of an Effective Material Handling System

An effective material handling system is crucial for optimizing operations and streamlining productivity. It involves incorporating key elements that contribute to efficient material movement, employee well-being, and environmental sustainability. The following elements play a vital role in creating an effective material handling system:

1. Material Handling Equipment

Material handling equipment forms the backbone of any efficient system. Conveyors, forklifts, and automated guided vehicles are essential tools for seamlessly transporting materials from one location to another. By choosing the right equipment for specific tasks, companies can greatly improve material flow, reduce manual labor, and enhance overall operational efficiency.

2. Automation

Automation is revolutionizing material handling processes by reducing human intervention, minimizing errors, and increasing throughput. With the integration of advanced technologies such as robotics and Artificial Intelligence (AI), repetitive and physically demanding tasks can be automated, freeing up employees to focus on more complex and value-adding activities. Automation not only improves productivity but also enhances safety and reduces the risk of workplace accidents.

3. Planning and Standardization

Efficient material flow requires careful planning, standardization, and simplification. By analyzing workflow patterns, organizations can identify areas of improvement, eliminate bottlenecks, and optimize the layout of their facilities. Standardizing processes and equipment ensures consistency, simplifies training, and facilitates continuous improvement efforts. This leads to smoother operations, faster order fulfillment, and reduced costs.

4. Ergonomics and Safety

Employee well-being is a top priority in any material handling system. Incorporating ergonomic principles and safety features into the design of workstations, equipment, and processes ensures that employees can perform their tasks comfortably, reducing the risk of injuries and promoting overall health. By creating a safe and ergonomically-friendly work environment, organizations can enhance employee morale, reduce absenteeism, and improve overall productivity.

5. Environmental Impact

As sustainability becomes increasingly important, organizations are striving to minimize their environmental footprint. Material handling systems can contribute to this goal through waste reduction, energy conservation, and responsible material disposal. By implementing practices such as recycling, reusing packaging materials, and utilizing energy-efficient equipment, companies can reduce their environmental impact, showcase their commitment to sustainability, and meet regulatory requirements.

Optimizing material handling with these key elements creates a foundation for success, enabling organizations to achieve operational efficiency, cost reduction, and overall productivity improvement.

Understanding the Nature of Material Handling and its Workflow

Material handling plays a crucial role in logistics operations, particularly in warehouse management. It encompasses the movement, protection, storage, and control of materials and products throughout various stages, including manufacturing, warehousing, distribution, and disposal. With the goal of enhancing efficiency, material handling focuses on optimizing workflows in these operations.

In a warehouse management setting, material handling involves key tasks such as receiving, shipping, storage, and order fulfillment. The efficient execution of these tasks is essential for maintaining a smooth logistics operation. By streamlining and automating material handling processes, businesses can achieve higher productivity, reduced costs, and improved customer satisfaction.

The Importance of Material Handling in Warehouse Management

Material handling systems are designed to optimize warehouse operations and improve overall industrial efficiency. These systems encompass a range of equipment and products that utilize advanced technologies, such as AI, robots, and machines, to automate logistics tasks and reduce the reliance on manual labor.

Implementing material handling systems offers several benefits. It helps overcome labor shortages and reduces physical strain on employees by automating repetitive tasks. This not only improves productivity but also enhances workforce well-being and morale. Additionally, material handling systems facilitate efficient loading, conveying, storage, sorting, and retrieving operations, resulting in streamlined processes and optimized productivity.

| Benefits of Material Handling Systems in Warehouse Management | Advantages |

|---|---|

| Improved Efficiency | Streamlined operations and reduced manual labor |

| Labor Savings | Automation of repetitive tasks and overcoming labor shortages |

| Enhanced Worker Safety | Reduced physical strain and improved well-being |

| Optimized Productivity | Efficient material handling processes and minimized downtime |

“Material handling systems optimize warehouse management operations by automating tasks and reducing manual labor, leading to improved efficiency and productivity.”

In conclusion, understanding the nature of material handling and its workflow is crucial for effective warehouse management. By streamlining and automating material handling processes, businesses can achieve higher productivity, cost savings, and improved worker safety. Material handling systems play a vital role in optimizing warehouse operations, ensuring streamlined processes and efficient utilization of resources.

Material Handling Systems and Their Importance

Material handling systems play a crucial role in enhancing industrial efficiency across various sectors, including manufacturing, distribution, and warehousing. These systems utilize advanced technologies, such as AI, robots, and machines, to streamline logistics operations and reduce manual labor. By automating tasks such as loading, conveying, storage, sorting, and retrieving, material handling systems optimize processes and contribute to overall operational success.

Implementing material handling systems offers several advantages for businesses. One significant benefit is the ability to overcome labor shortages by reducing the reliance on manual labor. This not only increases operational efficiency but also creates a more favorable working environment for employees. By minimizing physical strain and automating repetitive tasks, material handling systems improve workforce well-being and morale. Moreover, these systems enable companies to improve the overall efficiency of their logistics operations, leading to enhanced productivity and reduced operational costs.

In the manufacturing industry, material handling systems streamline production processes by seamlessly moving materials and products from one stage to another. They ensure a continuous flow of materials, eliminating bottlenecks and reducing downtime. This results in improved productivity and increased operational output. Similarly, in distribution and warehousing, material handling systems optimize storage, picking, and shipping operations. They enable efficient inventory management, accurate order fulfillment, and timely delivery, ultimately enhancing customer satisfaction.

Table: Comparative Analysis of Material Handling Systems

| System | Benefits |

|---|---|

| Conveyor Systems |

|

| Automated Guided Vehicles (AGVs) |

|

| Forklifts |

|

Table: Comparative Analysis of Material Handling Systems

When choosing a material handling system, it is essential to consider the specific operational needs and requirements. Conveyor systems, automated guided vehicles (AGVs), and forklifts are popular options that offer distinct benefits. Conveyor systems streamline material movement, reduce labor costs, and improve productivity. AGVs efficiently transport materials, increase flexibility, and enhance safety through obstacle detection. Forklifts enable efficient material handling in tight spaces, improve warehouse organization, and reduce material damage.

In conclusion, material handling systems are indispensable in achieving industrial efficiency. They automate logistics tasks, optimize processes, and improve overall operational output. By implementing these systems, businesses can overcome labor shortages, enhance productivity, and create a more favorable working environment. Whether it’s manufacturing, distribution, or warehousing, material handling systems play a vital role in streamlining operations and ensuring operational success.

The Conveyor Design Process and Safety Considerations

When it comes to optimizing material handling processes, the design of conveyor systems plays a crucial role. The conveyor design process involves carefully analyzing the product or material that will be handled, assessing the operational environment, and considering spatial constraints. By taking these factors into account, businesses can create custom conveyor solutions that fit their specific operational needs.

Safety is a paramount concern in conveyor system design. Adherence to safety standards and regulations is essential to protect the workforce and maintain a secure operational environment. By incorporating safety features such as emergency stop buttons, safety guards, and interlock systems, businesses can ensure the well-being of their employees while operating conveyor systems.

“Safety is not just a goal; it is a requirement. We prioritize the safety of our workforce by strictly adhering to safety standards and implementing comprehensive safety measures in our conveyor system design.”

Conveyor systems contribute to workforce well-being by reducing physical strain and automating processes. By eliminating manual material handling tasks, employees can focus on more mentally-demanding and value-added activities. Furthermore, conveyor systems enable the implementation of advanced technologies, such as automated sorting and tracking systems, which further enhance overall operational efficiency.

Ensuring Workforce Well-being

Ensuring the well-being of the workforce goes beyond safety considerations. Conveyor systems can be designed with ergonomic principles in mind, reducing the risk of musculoskeletal disorders and improving employee comfort. Height-adjustable conveyor belts, anti-fatigue mats, and ergonomic workstations are just a few examples of how conveyor systems can promote a healthier and more comfortable work environment.

In conclusion, the conveyor design process involves careful analysis, taking into account factors such as the product or material to be handled, the operational environment, and safety considerations. By prioritizing the safety and well-being of the workforce, businesses can design custom conveyor solutions that optimize material handling processes and enhance operational efficiency.

The Value of Custom Solutions in Conveyor Systems

When it comes to optimizing operational efficiency, custom solutions in conveyor systems design offer significant value. These tailored solutions are specifically designed to meet the unique operational needs of businesses, enhancing performance and maximizing productivity. Unlike off-the-shelf solutions, custom conveyor systems provide scalability, adaptability, and strategic investments that yield long-term benefits.

One of the key advantages of custom solutions is their ability to address unique operational needs. Off-the-shelf conveyor systems may not fully align with an operation’s specific requirements, resulting in inefficiencies and additional expenses over time. Custom solutions, on the other hand, can be designed to fit perfectly with the operation’s needs, ensuring optimal efficiency and reduced maintenance costs.

Another significant benefit of custom conveyor solutions is their scalability. Businesses can proactively adapt to future needs and expand their operations without major disruptions by implementing scalable conveyor systems. This flexibility allows for seamless integration of new processes and technologies, providing a strategic advantage in a rapidly evolving business landscape.

The Importance of Strategic Investment

Investing in custom conveyor solutions is a strategic decision that offers long-term benefits. While off-the-shelf solutions may appear more cost-effective in the short term, their limitations can lead to additional expenses and inefficiencies over time. Custom solutions, on the other hand, offer a higher return on investment by providing tailored solutions that optimize operational efficiency, reduce maintenance costs, and increase overall productivity.

By embracing the challenges and complexities of conveyor system design, businesses can unlock the full potential of their material handling processes. Custom solutions not only improve operational efficiency but also contribute to the overall success of the business by streamlining processes, enhancing productivity, and driving sustainable growth.

Investing in custom conveyor solutions is not only a strategic move but also a testament to a business’s commitment to operational excellence. By prioritizing efficiency, scalability, and strategic investments, businesses can optimize their material handling processes, stay ahead of the competition, and pave the way for long-term success.

| Benefits of Custom Conveyor Solutions | Off-the-Shelf Solutions | Custom Solutions |

|---|---|---|

| Alignment with operational needs | Limited customization | Tailored solutions for optimal efficiency |

| Scalability and adaptability | May require significant modifications | Seamless integration of new processes and technologies |

| Long-term cost savings | Potential additional expenses over time | Reduced maintenance costs and increased productivity |

Conclusion

Conveyor systems play a crucial role in optimizing material handling processes and improving operational efficiency. They automate material movement, reduce labor costs, increase productivity, and enhance workforce efficiency and morale. By prioritizing material handling optimization with conveyor systems, businesses can achieve cost reduction, product flow improvement, and overall operational efficiency.

Custom solutions tailored to specific operational needs offer scalability, adaptability, and strategic investments that yield long-term benefits. Embracing the challenges and complexities of conveyor system design leads to a future of efficient material handling and operational success.

With our expertise in conveyor system design and customization, we can help businesses unlock the full potential of their material handling processes. Our custom solutions are crafted to fit the unique needs of each operation, ensuring optimal efficiency, reduced maintenance costs, and a favorable return on investment. Partner with us to embrace the power of conveyor systems and achieve operational excellence through material handling optimization.

FAQ

What are the benefits of optimizing material handling with conveyor systems?

Optimizing material handling with conveyor systems can lead to reduced operational costs, enhanced product flow, and increased overall productivity.

How can conveyor systems improve time and space management?

Integrating conveyor systems can improve time and space management by reducing downtime and allowing employees to focus on more mentally-demanding tasks.

How do conveyor systems contribute to cost reduction in material handling?

Conveyor systems contribute to cost reduction in material handling by minimizing handling costs, preventing product damages, and increasing overall product quality.

What role do conveyor systems play in increasing productivity and efficiency?

Conveyor systems help increase productivity and efficiency by streamlining the material handling process and requiring fewer resources.

What are the key elements of an effective material handling system?

The key elements of an effective material handling system include material handling equipment, automation, planning and standardization, ergonomics and safety, and environmental impact considerations.

In which areas of logistics do material handling operations primarily focus?

In the logistics industry, material handling operations primarily focus on warehouse management tasks such as receiving, shipping, storage, and shipping of goods.

How do material handling systems optimize productivity in various industries?

Material handling systems optimize productivity by utilizing AI, robots, and machines to automate logistics tasks and reduce manual labor in loading, conveying, storage, sorting, and retrieving operations.

What factors are considered in the design of conveyor systems?

The design of conveyor systems involves analyzing the product or material to be handled, assessing the operating environment, considering spatial constraints, and ensuring adherence to safety standards and regulations.

What are the advantages of custom solutions in conveyor systems design?

Custom solutions in conveyor systems design offer tailored responses to unique operational needs, scalability, proactive adaptation to future needs, and strategic investments that yield long-term cost savings.

What are the benefits of prioritizing conveyor systems in material handling optimization?

Prioritizing conveyor systems in material handling optimization can lead to reduced costs, improved product flow, and overall operational efficiency.