Demand planning- An effective supply chain management process that can help you meet your audience’s demands while keeping costs down. Supply chain management and inventory management are challenges for business, and Gartner estimates 70% of businesses struggle to anticipate and react to demand, highlighting that demand planning is important.

Implementing a demand plan using a comprehensive planning solution can help you anticipate customer demand levels and adjust your inventory and logistics accordingly. There are several benefits to adopting demand planning, including ensuring that products are available where and when customers need them, reducing costs linked to inventory management and surplus, and scheduling labor more effectively.

There are a few key elements you will need to implement a demand planning process:

- Data. Relying on historical and real-time data will help you gain insight into behaviors from your customers.

- Market intelligence is crucial for demand planning as it helps in predicting consumer demand more accurately.. Studying broader market trends is crucial for anticipating shifts in demand.

- Enterprise Resource Planning software. An ERP tool is a central platform you can use to oversee operations, including supply chain management, inventory, accounting, purchasing, and more, effectively aiding in product portfolio management and enhancing your demand planning strategy.

- Inventory management process as part of demand management. Adopting a new process to manage your inventory will help you leverage insights from your data and market intelligence, aligning with strategies in demand planning is the process of forecasting.

- Monitoring. It’s important to monitor the performance of your demand planning and forecasting efforts so you can implement continuous improvement.

Analytics for Optimized Demand Planning

The global supply chain logistics market will grow at a rate of 6.7% between 2019 and 2023. The need to manage your supply chain more effectively increases as more businesses find themselves faced with a more complex environment. The current trend is for organizations to work with many suppliers and distributors on a global scale, which results in a more complex supply chain.

Analytics become an invaluable tool that can mine data from this complex supply chain, identify bottlenecks, and help you predict future demand, demonstrating how demand planning can improve business operations.

You can optimize demand planning by adopting real-time analytics to monitor demand and be more reactive, and to identify the factors that will influence demand in the future, following the best practices in the industry.

The Four Pillars of Demand Planning and Forecasting

Before going any further, it’s important to discuss the difference between demand planning and demand forecasting.

Demand Forecasting

Demand forecasting is about predicting what customer demand will be like at a future date. Demand forecasting typically uses data with techniques like historical sales data analysis or market research.

Demand Planning

Demand planning is a process that leverages the outcome of demand forecasting efforts to implement a demand plan. The purpose of demand planning is to ensure inventory levels and distribution can meet future demand levels and meet customer demand. Successful demand planners use inventory management, acquisition, logistics, and more to prepare for fluctuating demand levels, embodying the essence of demand planning is a multi-step process.

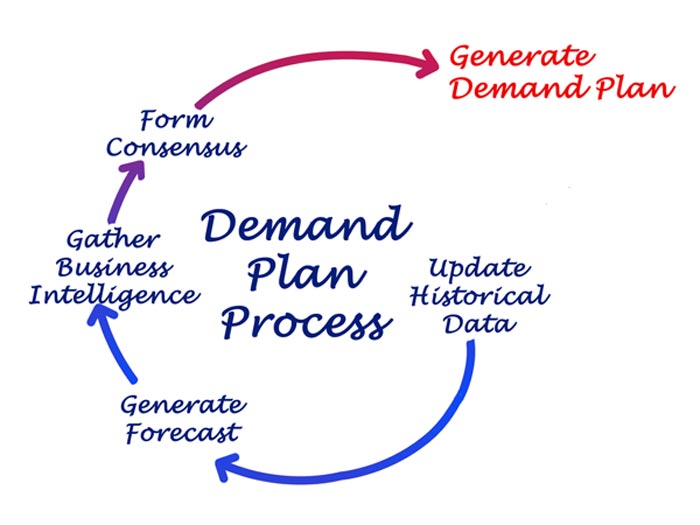

First Pillar: The Demand Planning Process

The demand planning process should span the entire supply chain, focusing on key steps to ensure inventory levels are adequate to meet customer demand. A comprehensive demand chain planning process should include managing relations with different suppliers and distributors, signing contracts with new supply chain partners, adjusting quantities of goods the business purchases, and determining where to store inventory.

Demand planning might also encompass deciding what the business does internally and which processes it will outsource, crucial steps include evaluating each process’s impact on overall efficiency. Demand planners are also responsible for identifying and resolving problems like gaps in fulfilling demand, surplus, or risks of supply chain disruption, showcasing the multifaceted role of planning is a supply chain necessity.

Second Pillar: Demand Forecasting

Demand forecasting is the process of predicting how demand will evolve in the future. The more accurate forecast is, the more cost-effective your demand planning process can be.

Challenges

There are some challenges to consider when implementing a sales forecast project. The first obstacle is data. You need quality historical data from the right sources to gain an accurate insight into trends.

Because demand forecasting relies on assumptions about how consumers will behave in the future, it’s essential to verify these assumptions. If you can’t verify an assumption, it’s wise to give it less weight when you implement a demand plan.

There are also factors that are difficult to predict, affecting the statistical forecast accuracy. In 2020, many businesses saw their supply chain disrupted because of COVID-19, along with some drastic changes in consumer behaviors and demand for certain products or services.

Example

Let’s take the example of a small restaurant to better understand how you can apply demand forecasting on a day-to-day basis. The food industry can see fluctuations in demand based on factors like the Weather, local events, and traffic are significant external factors that demand planning best practices consider in forecasting.

Looking at weather forecasts can help a restaurant owner predict sales volumes, as well as which menu items will be in demand. The restaurant owner would then adjust procurement to reflect these predictions, roll out new specials or adjust pricing, and schedule more staff members when they expect demand to increase.

Different Types of Demand Forecasting Strategies

There are different methods businesses use to forecast demand:

- Delphi method is among the best practices for qualitative forecasting.. This method relies on industry experts who make predictions based on their experience and expertise.

- Conjoint analysis. This approach focuses on the features of a product. There is an assumption that customers make trade-offs and will select the product that has the most features they want. Conjoint analysis predicts demand based on in-demand features and other product offerings available to customers.

- Time series. A time series analysis, part of the chain management process of forecasting demand for products, looks at historical data, including sales volumes. It’s a popular option for identifying seasonal shifts in demand, a critical aspect of demand management.

- Surveys, when considered as a demand for a product metric, can enrich demand planning and are integral to understanding consumer demand.. You can use surveys to keep track of purchasing intent.

These methods include a mix of qualitative and quantitative analysis and demonstrate why demand planning requires a comprehensive approach. It’s best to use a mix of both statistical and qualitative methods to get a more comprehensive picture and meet customer demand.

Regardless of the demand forecasting method you choose to use, there are two possible approaches:

- Top-down. A top-down approach starts with the big picture. You could, for instance, begin your analysis with market data and predict shifts in customer demand based on how many market shares your business has.

- Bottoms-up approaches in forecasting focus on the lifecycle of products.. A bottoms-up approach begins with internal data like sales volume for your different channels or traffic for your website.

Third Pillar: Preparing for the Future

Demand planning and forecasting, incorporating statistical forecasts, are evolving at a fast pace. There are new possibilities to explore for operations planning thanks to technologies like analytics, machine learning, and artificial intelligence.

While many businesses already rely on analytics for demand planning and shape demand, few leverage the full potential of predictive analytics. Machine learning technology can model your supply chain and extract insights that reflect how customers behave and why.

Artificial intelligence can analyze a wide range of internal and external sources and factors, incorporating statistical methods to forecast demand more accurately, demonstrating how planning is a multi-step process. Modeling techniques can also help you compare the outcome of different inventory management and increase your understanding of what works best for your organization. This approach can help you in optimizing your product portfolio management. reduce inventory by 10 to 30% To cut down on costs, companies must leverage demand planning best practices effectively.

Fourth Pillar: Demand Forecasting Software

Enterprise Resource Planning software is a must-have tool for effective demand planning. It acts as a central platform from which you can manage different processes, including accounting, procurement, risk management, compliance, supply chain, and more.

Using a centralized platform breaks down silos between these processes and improves collaboration. It also helps you collect data for your different processes and optimize them.

Using ERP software by itself isn’t sufficient. You need to combine it with a demand planning software. Adopting a demand planning software will help you get more out of the data collected thanks to your ERP, facilitating a more nuanced understanding of future demand based on historical data. For instance, the company ASK Power was able to increase its on-time deliver rate to 99% after rolling out a supply chain planning and supply chain execution solution to collect data from its ERP system and use it to create supply chain forecasts.

FAQs:

Here are some common questions about demand planning and forecasting.

How can demand planning improve the supply chain?

Anticipating fluctuating demand levels helps you adjust the quantities you purchase and gives you the possibility to secure the best price possible for the volumes you need, which is at the core of demand planning is a supply chain strategy. You can anticipate which distribution channels are going to be busy and plan accordingly, and be more reactive by seeking new suppliers before demand increases.

What are the different aspects of demand planning?

Demand planning starts with demand forecasting, setting the foundation for a planning strategy that helps meet customer demand more effectively. Once you have an idea of what demand will be like in the future, you can develop a demand plan and implement it. Your demand plan would typically cover acquisition, inventory storage, distribution channels, plans for shipping orders, pricing, and scheduling labor, all integral parts of a comprehensive planning strategy.

Why is demand planning important?

Effective demand planning gives you a competitive edge. It decreases the risks of not being able to fulfill demand and can reduce costs linked with an inventory that you’re not selling.

How is demand planning evolving?

Demand planning is becoming more complex as a growing number of businesses find themselves managing global supply chains with several suppliers and distributors. New technologies like predictive analytics are becoming more accurate, and innovations like AI and machine learning give you the possibility to extract models from your data and make better predictions.

How do you learn demand planning?

You can pursue a degree in business administration or computer science to become a demand planner and learn more about demand planning. It’s best to complete coursework in areas like analytics and project management.

What makes a good demand planner?

A demand planner should possess strong analytical skills, understand statistical methods, and think outside the box to meet customer demand, highlighting why demand planners need to continuously develop their skills. You will need solid tech skills and should be ready to adapt since the future of demand planning is evolving at a fast pace, emphasizing the agility of a demand planning team.

Q: What are the key steps involved in demand planning and forecasting?

A: The key steps in demand planning and forecasting include analyzing historical data, identifying trends, collaborating with stakeholders, creating a demand forecast, validating the forecast, and adjusting strategies as needed.

Q: How can demand planning software improve forecast accuracy?

A: Demand planning software can improve forecast accuracy by leveraging advanced algorithms, analyzing large datasets, incorporating market trends, improving collaboration among departments, and providing real-time updates on demand changes.

Q: What are the best practices for demand planning to meet customer demand effectively?

A: Best practices for demand planning include utilizing statistical models, incorporating input from sales and marketing teams, aligning supply chain activities with demand forecasts, regularly reviewing and adjusting forecasts, and investing in employee training for enhanced forecasting skills.

Q: How does demand planning differ from production planning and sales and operations planning?

A: Demand planning focuses on predicting customer demand for products, whereas production planning involves scheduling and managing production resources to meet that demand. Sales and operations planning integrates sales forecasts with production plans to ensure alignment across the supply chain.

Q: What is the future of demand planning in the context of supply chain management?

A: The future of demand planning in supply chain management is moving towards enhanced digitalization, automation of forecasting processes, real-time data analytics, AI-driven insights, and a more customer-centric approach to meet evolving market demands effectively.

Q: How can demand planners choose the most suitable demand planning software for their organization?

A: Demand planners can choose the most suitable demand planning software by assessing their specific needs, evaluating software features such as forecasting algorithms, collaboration tools, scalability, integration capabilities, user interface, and seeking recommendations from industry experts.

Q: Why is accurate demand planning crucial for meeting customer demand for products?

A: Accurate demand planning is crucial for meeting customer demand for products as it helps in optimizing inventory levels, reducing stockouts, improving customer satisfaction, minimizing excess inventory costs, enhancing operational efficiency, and staying competitive in the market.

Conclusion

As supply chains continue to grow in scale and complexity, demand planning and forecasting are establishing themselves as key aspects of business planning, central to choosing demand planning software that meets these expanding needs. These processes allow businesses to anticipate demand, keep the right items in stock, and reduce costs by adhering to demand planning best practices.