Heat treated pallets have a range of practical applications in supply chains, particularly for exports. Since wood pallets are made from an organic material, they can potentially absorb and collect pests, insects, and other contaminants. Heat treatment for pallets is a crucial precaution to guarantee that all export shipments comply with international safety standards. Heat treatment also protects the integrity of products within the supply chain, especially in export shipments.

Read on or contact us to discover the benefits of heat treatment for your supply chain. Here’s every detail you need to know about heat-treated pallets for export.

What Is Heat Treatment?

Heat treated wood pallets, also known as HT pallets, are essential for international shipping. These heat treat pallets are designed to meet the strict regulations for exporting goods across borders. The heat treated wooden pallets are durable and sturdy, making them ideal for transporting heavy loads.

Heat treated pallets in English are clearly labeled with the international symbol for heat treatment, ensuring that they meet the necessary standards. When shipping goods overseas, it is important to use heat treated skids on heat treated pallets to prevent any issues with customs. The heat treated pallet wood undergoes a specialized heating process that eliminates pests and pathogens, making it safe for use in international shipping. Choose heat treated pallets for peace of mind when shipping goods abroad.

The process of pallet heat treating involves warming the materials to a specified temperature crucial for export. The material, after being heated to about 132.8 degrees, is maintained at that temperature for a measured amount of time before being cooled at a prescribed rate. Heat treatment is a method used for the wood to obtain the required properties for specific jobs, types of pallets used in shipments, and various applications.

Heat treatment is a process used to sanitize material developed by the IPPC (International Plant Protection Convention) to secure, prevent, and control the spread of plant pests. The heat treatment process ensures that the pallets are sanitized, safe, clean, and ready for the job.

What Are Heat Treated Pallets and How Was It Treated?

Heat-treated pallets go through a standard heat treatment that allows the material to be disinfected. In order to treat the types of pallets and other wood packaging materials used in exports, they are heated to a significant core temperature of 140 degrees.

The elevated temperature of the pallet, around 132.8 degrees Fahrenheit, is sustained for at least 30 minutes to ensure that all undesirable contaminants are removed, thereby meeting the ISPM-15 regulations. Pallets are treated with heat to eliminate any insects and destroy larvae in the wood, debarking them and making them ready and compliant for export.

ISPM 15-Compliant Heat-Treated Wood Pallets

ISPM 15 stands for International Standards for Phyto-sanitary Measures No. 15 and applies to all wood products, wood packaging, wood pallets, and crates. Pallets in compliance with ISPM 15 have been heat-treated and are guaranteed safe for international shipments.

According to the standards of ISPM 15, all pallets must be treated for pests through one of the approved methods such as heat treating, fumigation, vacuuming, and steaming. Heat treatment is the best way for companies to ensure their products and shipment materials comply with ISPM 15.

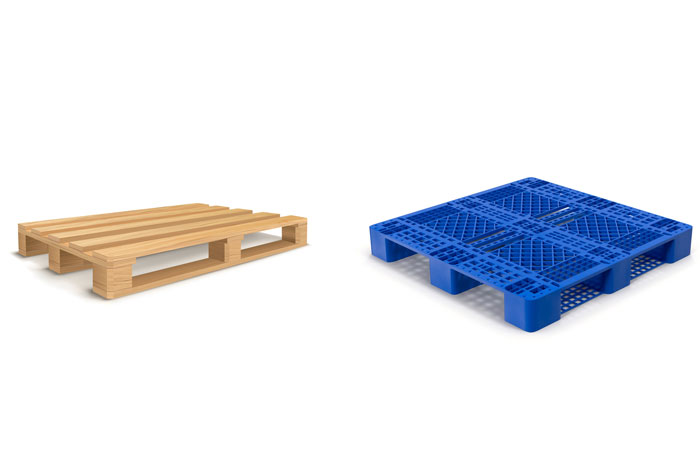

Heat-Treated Wood Pallets vs. Plastic

Plastic pallets also have benefits for international shipping, such as not having to worry about whether they were heat-treated since plastic is not a good host for insects and pests. Plastic also does not retain moisture as well as wood.

However, the cost of polymer or plastic-based pallets can overshadow their benefits. Plastic pallets are also a burden on a company’s environmental footprint. With many enterprises becoming more conscious lately, green compliance is also something to consider. Wooden pallets are more cost-effective and, when heat treated, are as safe and sanitary as any plastic.

Why Do Pallets Need To Be Heat-Treated?

Pallets need to be heat-treated to ensure that they are safe to ship internationally. Heat treatment eliminates insects that can cause harm to foreign environments if spread through the pallet shipments. Companies can easily comply with international shipment requirements by working with heat-treated pallets.

While pallets can be decontaminated of pests in various ways, heat treatment is considered the more environmentally friendly alternative when compared to fumigation techniques.

Another benefit of heat-treated pallets is that they are free of potential fungi. Heat-treated pallets are free of possible contaminants that can harm the products being packaged and shipped – especially for food products.

How Do I Know if I have a Heat-Treated Pallet?

Pallets that have been heat-treated should have a particular stamp on the side of the wood. Look for the IPPC (International Plant Protection Convention) stand to determine if the pallets have been treated. If a pallet has been heat-treated, it should be marked with an “HT,” indicating that it was heat treated and did not come into contact with any chemicals during the process. Pallets marked with “MB” have likely come into contact with methyl bromide and should be avoided.

EPAL Pallets and Euro Pallets? Are Euro Pallets Heat-Treated?

Euro Pallets are also known as EPAL pallets. These particular pallets are the standard European pallet and specified by the European Pallet Association (EPAL). European standard pallets that comply with the national standardization are eligible for the EPP (The European Pallet Pool). The EPP is a system that allows shipments to exchange pallets for pallets.

Is a Pallet Made of Plywood and Composite Blocks Considered a Heat-Treated Pallet?

To put it simply: No. Pallets that are created from manufactured woods do not need to be treated. Manufactured wood pallets such as plywood pallets and OSB (oriented strand board) pallets do not need to be treated. Particleboards also will not require heat treatment.

While manufactured wood can be treated, it is unnecessary as any potential insects or pests are destroyed and eliminated during the manufacturing process. Rather than heat treatment, manufactured wood materials can be fumigated to ensure that they are free of any pests before shipments.

Does My Heat-Treated Pallet (HT) also have fungicides?

How do you know if your wooden pallets have been treated with pesticides and fungicides? As mentioned above, heat-treated pallets will bear the mark “HT,” which indicates heat treatment. Pallets with the “MB” mark have been treated with methyl bromide, a toxic pesticide.

While methyl bromide effectively eliminates insects and pests from the wood, it is also known to be linked to health problems in humans. Methyl bromide is also harmful to the earth’s environment and causes issues with the ozone layer.

Companies and manufacturers should avoid both the “MB” mark and unmarked pallets, which have likely been in contact with harmful chemicals

Frequently Asked Questions (FAQ’s)

Q: What are heat treated pallets?

A: Heat treated pallets are wooden pallets that have been subjected to a specific heat treatment process to meet international standards for phytosanitary measures (ISPM 15). This process involves heating the pallets to a minimum core temperature of 56°C for a specific duration to eliminate pests and reduce the risk of pest infestation during international trade.

Q: Why should I use heat treated pallets for export?

A: Using heat treated pallets for export is essential to comply with ISPM 15 standards, which are incorporated into U.S. and international regulations for phytosanitary measures. These pallets reduce the risk of pest infestation, ensuring that your goods meet the required standards for international trade.

Q: How do I ensure that the pallets I use are ISPM 15 compliant?

A: To ensure that the pallets you use are ISPM 15 compliant, you should look for the ISPM 15 mark or stamp on the pallets, which indicates that they have been heat treated and meet the necessary standards for phytosanitary measures.

Q: Can I use recycled wood for heat treated pallets?

A: Yes, recycled wood can be used for heat treated pallets as long as it meets the requirements for heat treatment and is free from any signs of pest infestation. Using recycled wood for pallets is a sustainable practice that contributes to environmental conservation.

Q: What are the benefits of using heat treated pallets?

A: Using heat treated pallets reduces the risk of pest infestation during international trade, ensures compliance with ISPM 15 standards, and promotes the use of sustainable and environmentally friendly materials. These pallets are safe, reliable, and essential for transporting goods internationally.

Q: What temperature is used in the heat treatment of pallets?

A: The heat treatment process for pallets involves heating them to a minimum core temperature of 56°C. This temperature is effective in eliminating pests and meeting the ISPM 15 requirements for phytosanitary measures.

Q: Can untreated wood pallets be used for transporting goods internationally?

A: Untreated wood pallets are not suitable for transporting goods internationally as they pose a higher risk of pest infestation and may not comply with ISPM 15 standards. It is essential to use heat treated pallets to meet the necessary phytosanitary measures for international trade.

Q: How can I find a reliable heat treated pallet manufacturer?

A: Finding a reliable heat treated pallet manufacturer involves researching companies that specialize in producing ISPM 15 compliant pallets. Look for manufacturers with a strong reputation, experience in international trade, and a commitment to using heat-treated wood materials.

Q: What is the process of heat treating wood pallets?

A: The process of heat treating wood pallets involves subjecting the pallets to a specific temperature, typically 56°C, for a specified duration to eliminate pests and meet ISPM 15 requirements. This process may also involve debarking the wood to ensure thorough heat treatment.

Q: How can I contact you for any questions about our heat treated pallets?

A: You can contact us for any questions about our heat treated pallets by reaching out to our customer service team through the contact information provided on our website. We are happy to assist you with any inquiries regarding heat treated pallets and their use for international trade.

Final Thoughts on Heat-Treated Pallets

There are many benefits to working with heat-treated pallets – especially for those who want to avoid fumigation or any contamination or infestation. Heat treatment is the most environmentally friendly way to ensure that all pallets, crates, and wood packaging material is safe and pest-free before traveling internationally.

Heat treatment protects both the products and the shipment from pests and allows companies to easily comply with necessary sanitation requirements for international shipments.

Pingback: how to attach a chain hoist to a yanmar 4jh