If you’re looking to improve your material movement process, it’s time to consider the benefits of advanced conveyor technology. Conveyors have become an essential part of manufacturing, warehousing, and distribution operations, providing efficient and automated handling of materials. By utilizing conveyor systems, you can improve your productivity, reduce labor costs, and enhance safety in your workplace.

From moving heavy loads to transporting delicate materials, conveyor technology can cater to various load types, making your material movement process seamless and efficient. Whether you’re starting a new facility or upgrading an existing one, understanding the different applications and benefits of conveyor systems can help you make informed decisions.

Key Takeaways:

- Conveyor technology can optimize your material movement process.

- Conveyors can handle various load types, making your process more efficient.

- By implementing conveyor systems, you can reduce labor costs and improve safety.

- Understanding conveyor applications and handling techniques is essential for successful material movement.

- Investing in conveyor technology can significantly enhance your overall operational performance.

Conveyor Applications for Improved Material Movement

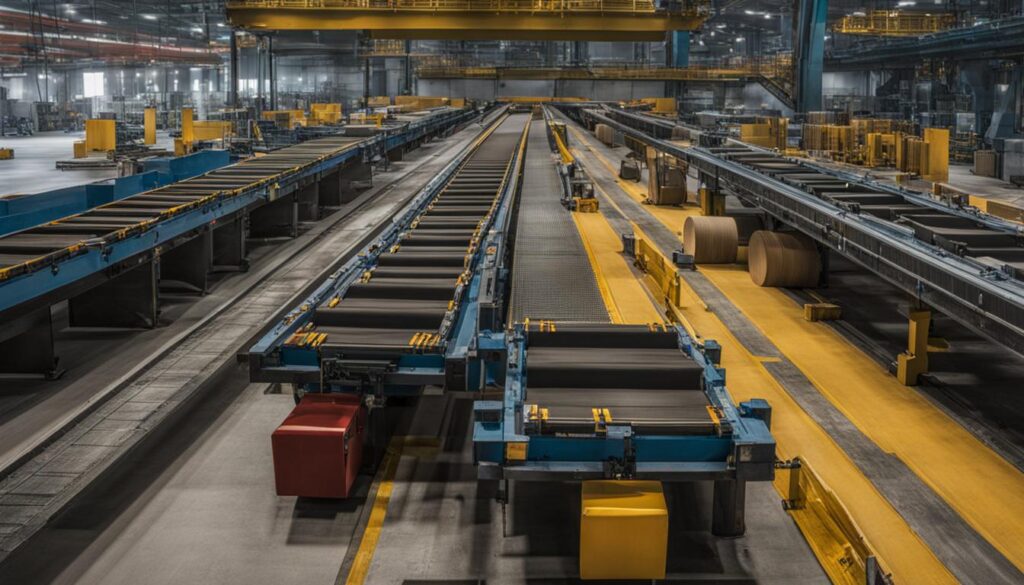

When it comes to material movement, conveyors are an essential tool for any facility seeking to increase productivity and efficiency. The ability to move materials seamlessly through different stages of your operation can significantly reduce manual labor requirements while minimizing the risk of damage or errors.

By utilizing different types of conveyors, you can tailor your material movement process to your specific needs. For example, roller conveyors are ideal for transporting heavy loads, while belt conveyors are better suited for lighter materials that require more precise handling.

Another popular type of conveyor is the gravity conveyor, which uses the force of gravity to move materials down an incline or decline. This type of conveyor is useful when handling small packages or when you need to move materials between different levels of your facility.

Conveyor Applications for Improved Material Movement

When it comes to conveyor applications, there are several key areas where they can significantly enhance your material movement process:

- Assembly Lines: Conveyors can be used to transport materials between different stages of an assembly line, reducing the need for manual handling and increasing efficiency.

- Warehousing: Conveyors can be used to transport materials to and from storage locations, reducing the time and labor required to move materials within your facility.

- Distribution Centers: Conveyors are often used to sort and move packages in distribution centers, enabling materials to be transported quickly and efficiently.

By incorporating conveyors into your material movement process, you can streamline your operations, reduce labor costs, and increase efficiency.

“Conveyors are an essential tool for any facility seeking to increase productivity and efficiency.”

Handling Techniques for Optimal Material Movement

Proper handling techniques are essential for maximizing the benefits of conveyor technology in material movement processes. By following industry-standard practices, you can ensure your conveyor systems operate efficiently and effectively. Here are some handling techniques that can help you optimize your material movement:

- Ensure uniform loading and unloading: Uneven load distribution can cause conveyor jams, leading to production delays. Make sure the load is evenly distributed across the conveyor, using appropriate loading and unloading equipment such as forklifts, cranes, and pallet jacks.

- Maintain conveyor speed: Conveyor speed must be consistent to avoid unnecessary wear and tear on equipment parts and to eliminate unnecessary production down-time.

- Regular maintenance: Conduct routine maintenance checks on your conveyor systems to detect issues early and prevent equipment failure. This includes aligning belts, checking pulleys, and lubricating moving parts.

- Train your staff: Train your staff on proper handling techniques and routine maintenance tasks to ensure optimal performance and minimize the risk of injuries and accidents.

By integrating these techniques into your material movement processes, you can maximize the benefits of conveyor technology and achieve a seamless and efficient operation.

“Proper handling techniques are essential for maximizing the benefits of conveyor technology in material movement processes”

Enhancing Efficiency in Material Movement with Conveyor Systems

Integrating conveyor systems into your material movement process can significantly enhance efficiency. Here are some of the ways automated conveyor solutions can improve your operations:

| Benefits of Conveyor Systems for Material Movement | |

|---|---|

| Reduced manual labor requirements | |

| Conveyor systems can move materials along a predetermined path with minimal human intervention, reducing the need for manual labor and increasing operational efficiency. | |

| Reduced risk of errors or damage | |

| Conveyor systems can transport materials with precision, minimizing the risk of errors or damage during transportation, which can be a common issue with manual handling. | |

| Improved throughput | |

| Conveyor systems can move materials at a consistent pace, reducing bottlenecks and improving overall throughput. |

In addition to the above benefits, conveyor systems can also provide real-time data on material movement, allowing for better tracking and analysis. This can help identify areas of improvement and optimize processes for even greater efficiency.

Advanced Conveyor Technology for Different Load Types

Advanced conveyor technology has revolutionized material movement in manufacturing and distribution facilities. With specialized conveyors designed for different load types, you can ensure that your materials are transported with precision and care.

For heavy-duty loads, such as large machinery or bulk materials, powered roller conveyors provide a sturdy and efficient solution. These conveyors are designed to handle heavy loads and can be customized with various roller sizes to accommodate different load types.

If you’re working with delicate materials like electronics or glass, belt conveyors may be the better choice. These conveyors feature a smooth, continuous surface that reduces the risk of damage to fragile materials during transportation.

For facilities with limited space, vertical conveyors can help optimize your material movement process while minimizing the amount of horizontal space required. These conveyors can lift materials vertically, allowing you to transport materials between multiple levels of your facility.

Case Study: Conveyor Solutions for Beverage Manufacturing

| Powered Roller Conveyor | Belt Conveyor | Vertical Conveyor | |

|---|---|---|---|

| Load Type | Heavy Bottles and Cans | Glass Bottles | Empty Bottles |

| Benefits | Efficient Movement, Customizable Rollers for Different Load Sizes | Smooth Conveyor Surface for Delicate Materials | Vertical Movement, Space Optimization |

| Results | Reduced Manual Labor, Increased Productivity | Minimized Damage to Glass Bottles | Optimized Space Usage |

As demonstrated in the case study above, utilizing advanced conveyor technology for different load types can improve efficiency, reduce manual labor, and minimize the risk of damage to your materials. Evaluate your facility’s load types and transportation needs to determine which specialized conveyor solutions would be most beneficial for your operations.

Conclusion

Integrating advanced conveyor technology into your material movement process can significantly enhance your productivity, efficiency, and overall operational performance. By understanding the benefits and applications of conveyor systems, you can streamline your processes and elevate your material movement to new levels of success.

Through effective handling techniques, you can optimize conveyor technology to meet your unique facility needs. From reducing manual labor requirements to integrating automated systems, these techniques can help you maximize productivity.

By investing in advanced conveyor technology, you can enhance your operations, reduce the risk of errors or damage, and handle different load types with precision and care. Explore the advancements in conveyor technology today to discover specialized conveyors designed to meet your material movement needs.

By incorporating conveyor systems into your facility, you can not only improve your material movement process but also increase your operational efficiency. Experience the transformative impact that conveyor technology can have on your operations, and take the first step towards optimizing your facility today.

FAQ

How can conveyor technology enhance material movement?

Conveyor technology can enhance material movement by providing a smooth and efficient transportation system. It reduces manual labor requirements, minimizes the risk of errors or damage, and improves overall productivity and operational performance.

What are the various applications of conveyors in material movement?

Conveyors can be utilized in various applications for material movement. They can handle different load types, ensuring smooth transportation within your facility. Whether you need to move heavy machinery or delicate materials, there are specialized conveyors designed to handle a variety of loads with precision and care.

What are some effective handling techniques for optimal material movement with conveyor technology?

To optimize material movement with conveyor technology, it is important to follow proper handling techniques. This includes ensuring proper loading and unloading procedures, integrating automated systems, and streamlining processes. By implementing these techniques, you can maximize efficiency and productivity in your operations.

How can conveyor systems enhance efficiency in material movement?

Conveyor systems greatly enhance efficiency in material movement. They reduce the need for manual labor, leading to time and cost savings. Conveyor systems also minimize the risk of errors or damage during transportation, resulting in smoother and more reliable operations overall.

What advancements in conveyor technology cater to different load types?

Advancements in conveyor technology have led to specialized systems that cater to different load types. Whether you are handling heavy machinery, delicate materials, or any other specific load, there are conveyor solutions designed to handle them with precision and care. These advancements ensure that your materials are transported safely and efficiently.

Why should I invest in conveyor technology for material movement?

Investing in conveyor technology for material movement offers numerous benefits. It can significantly improve productivity, efficiency, and overall operational performance. By understanding the various applications, handling techniques, and advantages of conveyor systems, you can elevate your material movement to new levels of success.